An undoubted strength to compliment EDG's proven record with power systems for utility companies.

Today's

electric utilities have load management capabilities thought impossible

a few years ago. Imagine being able to turn off the hot water heater

in every eighth residence for 6.25 minutes each half-hour; all via

satellite transmission! With minimum load growth, utilities may

profit from better load management in lieu of increased plant investment.

Today's

electric utilities have load management capabilities thought impossible

a few years ago. Imagine being able to turn off the hot water heater

in every eighth residence for 6.25 minutes each half-hour; all via

satellite transmission! With minimum load growth, utilities may

profit from better load management in lieu of increased plant investment.

In this area, EDG has recently automated two 20-year-old

hydro power plants for the Grant County PUD  in

Epharata, Washington. A DCS system is used to provide the database

for integrated load dispatch and energy management at the central

dispatching office. Smart Distributed Processing Units are used

to control the start/stop sequence and the automatic synchronizing

of 20 generating units, 10 each at the Priest Rapids and Wanapum

Dams. PID loop controls are employed to achieve uniform temperatures

in transformers and generators and to improve turbine efficiencies.

in

Epharata, Washington. A DCS system is used to provide the database

for integrated load dispatch and energy management at the central

dispatching office. Smart Distributed Processing Units are used

to control the start/stop sequence and the automatic synchronizing

of 20 generating units, 10 each at the Priest Rapids and Wanapum

Dams. PID loop controls are employed to achieve uniform temperatures

in transformers and generators and to improve turbine efficiencies.

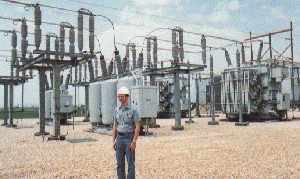

In another application,

the Corpus Christi electric utility is supplying power to a new

grass roots petrochemical plant in Bay City, Texas. EDG engineered

a SCADA system to monitor and control two 138KV incoming lines and

associated OCBs, two 25 MVA transformers, the 15KV secondary switchgear

and 18 unit substations through the one square mile complex. One

thousand I/0 points are available to monitor the status of the OCBs,

transformers, all protective relaying equipment, and to measure

analog values of voltages, currents, KW and KVAR demand. The SCADA

system provides automatic power factor control and maintains a perpetual

history of high and low currents for all feeders. The entire system

is scanned 150 times per second and alarm events are time-tagged

to the nearest 10 milliseconds before being stored and printed.

In another application,

the Corpus Christi electric utility is supplying power to a new

grass roots petrochemical plant in Bay City, Texas. EDG engineered

a SCADA system to monitor and control two 138KV incoming lines and

associated OCBs, two 25 MVA transformers, the 15KV secondary switchgear

and 18 unit substations through the one square mile complex. One

thousand I/0 points are available to monitor the status of the OCBs,

transformers, all protective relaying equipment, and to measure

analog values of voltages, currents, KW and KVAR demand. The SCADA

system provides automatic power factor control and maintains a perpetual

history of high and low currents for all feeders. The entire system

is scanned 150 times per second and alarm events are time-tagged

to the nearest 10 milliseconds before being stored and printed.

For further information on EDG's control systems capabilities please click on any of the following :- Control systems in Petroleum, Water, Facilities, Tank Gauging and Inventory Systems.